Automatic shelf pillar rolling forming machine: the cornerstone of multiple fields

In modern industrial production and logistics warehousing systems, automatic shelf pillar rolling forming machines are playing an irreplaceable key role and are widely used in multiple important fields.

Logistics and warehousing industry: creating efficient storage architecture

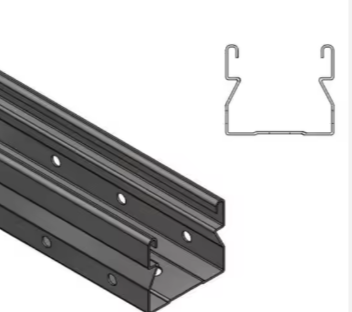

In logistics warehouses, massive amounts of goods need to be stored in an orderly manner, and the shelf columns made by the automatic shelf column rolling forming mechanism are the basis for building various types of shelves. Cross beam shelves have become the mainstream choice for storing various types of palletized goods due to their large load-bearing capacity and convenient access. The columns are precisely crafted by rolling forming machines to ensure a stable connection between the beams and columns, ensuring the stability of the shelf structure and bearing heavier goods. Drive in shelving is suitable for storing large quantities and a small variety of goods. Forklifts can directly enter the interior of the shelving for storage and retrieval, which requires excellent compression and impact resistance of the shelving columns. The columns made by the rolling forming machine have uniform material density and high structural strength, which can well meet this demand, maximize the use of storage space, and improve storage efficiency.

E-commerce and Express Delivery Industry: Warehousing Centers Supporting High Speed Operations

E-commerce and express delivery services are booming, and large warehousing centers have a huge volume of order processing. The shuttle style shelving system, combined with automatic guided vehicles (AGVs) and warehouse management systems, achieves efficient storage and rapid sorting of goods. Its core shelving columns are produced by automatic shelving column rolling forming machines. The precision of the columns manufactured by this equipment is extremely high, which can ensure that the height of each layer of the shelf is consistent, making it easy for automated equipment to accurately identify and store goods, greatly improving the turnover efficiency of e-commerce and express storage centers, and ensuring timely processing and distribution of orders.

Manufacturing industry: supporting lean production in factories

Wire rod racks and cantilever racks are widely used in manufacturing factories. Wire rod shelves have high flexibility and can be freely combined according to production needs to store various production components and tools. Cantilever shelves are suitable for storing long and flat goods, such as metal pipes, wood, etc. The columns produced by the automatic shelf column rolling forming machine can adapt to different types of shelves, meet the requirements of material classification storage and quick retrieval in manufacturing workshops, optimize production processes, reduce material handling time, and achieve lean production.

Supermarkets and Retail Industry: Creating a Convenient Shopping Environment

Supermarket display shelves should not only be aesthetically pleasing, but also stable and safe. The shelf columns produced by the automatic shelf column rolling forming machine can support various types of shelves and hooks, displaying a wide range of products. In warehouse style supermarkets, heavy-duty shelf columns carry a large amount of goods, and the rolling forming process endows the columns with good rigidity and toughness, ensuring that the shelves do not deform during long-term and frequent use, providing consumers with a safe and comfortable shopping environment.

Copyright © Cangzhou Guochen Cold Bending Machinery Equipment Co., Ltd. Rights Reserved Sitemap | Technical Support