Price:

Detailed Introduction

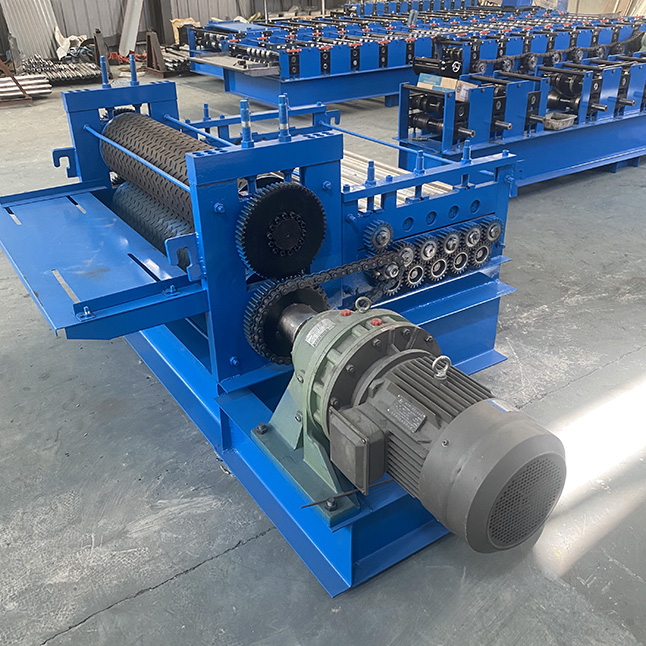

Embossing machine is a kind of equipment that presses patterns or designs on the surface of various materials.

Embossing machine: mainly used for embossing metal plates, such as color steel plates, aluminum plates, stainless steel plates, etc. It can emboss color steel plates with a thickness of less than 0.2-0.7mm and a width of less than 1500mm.

The main core component of the steel plate embossing machine is the embossing roller. The embossing roller usually uses a seamless steel pipe for the roller body and then processes it. The processing is divided into turning and welding.

Turning: Turning the matching parts of the roller body, end plate and shaft head, and the various parts of the steel roller body are roughly and finely turned to the required size of the drawing, and then the center frame is set up, the end face is turned, and the hole is drilled to the size;

Welding: Roller body inner tube welding: Correct the coaxiality of the two end shafts and the inner sleeve, and only weld the inner end plate on the shaft head. Put the inner sleeve into the roller body and weld the matching interface between the inner end plate and the roller body.

Steel plate embossing machine, metal embossing machine embossing roller installs the outer end plate on the two end shafts, and welds the outer end plate and the joint surface of the shaft and roller body. The next step is annealing and drilling. The roller blank is annealed to eliminate internal stress; one end of the steel roller shaft is flattened and the standard center hole is drilled. Then the pattern is processed, and the pattern is processed on the roller surface according to the customer's pattern requirements.

Main structural components

Embossing roller: It is the core component of the embossing machine, usually composed of a pair of upper and lower concave and convex rollers. The patterns of the upper and lower rollers match each other. By applying pressure to the material, the required pattern is formed on the surface of the material.

Transmission system: responsible for transmitting power to the embossing roller so that it rotates at the set speed and direction. It generally adopts gear transmission, chain transmission or belt transmission.

Pressure regulation system: used to adjust the pressure of the embossing roller on the material to adapt to the thickness and hardness of different materials, as well as the required embossing depth and effect. Common pressure regulation methods include screw pressure, hydraulic pressure, etc.

Control system: realizes automatic operation and monitoring of the embossing machine, including motor start and stop, speed regulation, pressure control, temperature control and other functions. It can also set fault alarm and safety protection devices to ensure the normal operation of the equipment and the safety of the operator.

Working principle

The embossing roller is rotated by the motor-driven transmission system, and the material to be processed is fed between the upper and lower embossing rollers. Under the pressure applied by the pressure regulation system, the pattern on the surface of the embossing roller is embossed onto the surface of the material, thereby achieving the embossing effect. For some embossing machines that require heating, such as some metal embossing machines, the material will also be heated during the embossing process to make the material easier to deform in order to obtain a clearer and more durable embossing effect.

Application field

Construction industry: used to produce building materials such as color steel composite panels and metal carved panels to increase the aesthetics and decorativeness of the panels, and also to improve the strength and durability of the panels.

Copyright © Cangzhou Guochen Cold Bending Machinery Equipment Co., Ltd. Rights Reserved Sitemap | Technical Support