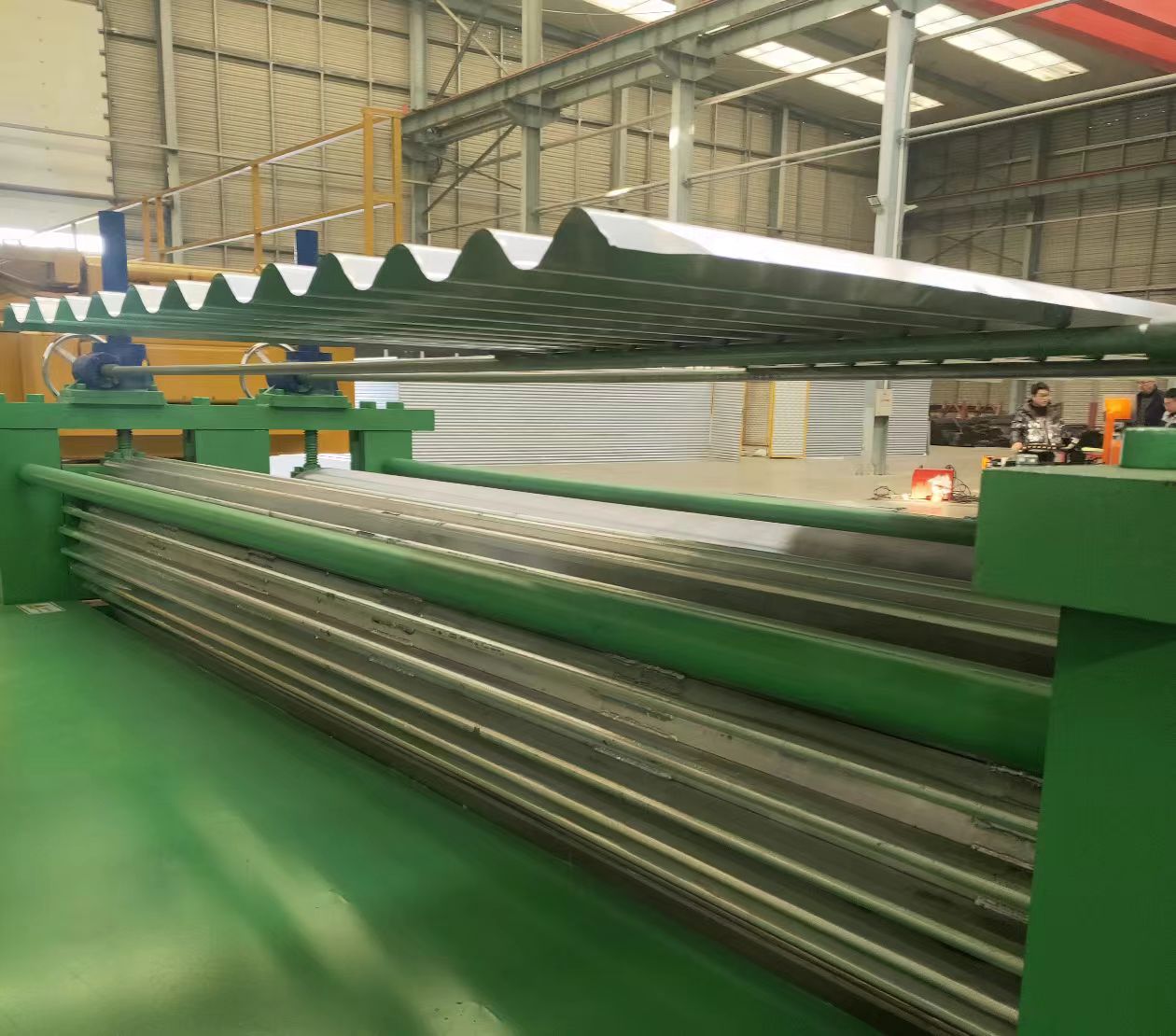

TAG: Aluminum roof panel manufacturing machine Rapid galvanized thin corrugated paper forming machine Hot selling horizontal corrugated paper forming machine

Price:

Detailed Introduction

1. Efficient metal roof panel rolling forming machine, precise size, high flatness of the panel, small error, fast output, creating sturdy and durable metal roofs!

2. Choose the Guochen rolling forming machine to easily process metal roof panels with one click, which is efficient, stable, and reliable in quality!

Are you still troubled by the formation of metal roof panels? This rolling forming machine is easy to operate, forms quickly, and can easily handle various projects

Choosing a horizontal roof corrugated sheet rolling forming machine can be considered from the following aspects:

production capacity

-Production demand: Determine the production speed and output of the equipment based on its own production scale and order quantity. For large-scale production, it is necessary to select efficient equipment that can produce a certain length of board per minute and can work continuously.

-Specification range: Consider the width, thickness, and ripple size range that can be processed for sheet metal. Common board widths include 1 meter, thicknesses range from 0.3-1.5 millimeters, and ripple heights range from 15-50 millimeters, in order to meet diverse production needs.

equipment performance

-Rolling accuracy: High accuracy is necessary to ensure that the corrugated shape of the sheet is regular and the size is accurate, reducing the rate of defective products. If the height error of the rolled ripples is within ± 1 millimeter, the flatness of the plate shape is high.

-Stability: Stable equipment can reduce downtime caused by malfunctions and improve production efficiency. You can check whether the mechanical structure design of the equipment is reasonable, and the quality and brand of key components such as motors, reducers, rollers, etc.

-Automation level: Equipment with high automation level can improve production efficiency and quality stability, such as automatic feeding, feeding, cutting, counting and other functions, and even remote monitoring and operation can be achieved through PLC control system.

Copyright © Cangzhou Guochen Cold Bending Machinery Equipment Co., Ltd. Rights Reserved Sitemap | Technical Support