Price:

Detailed Introduction

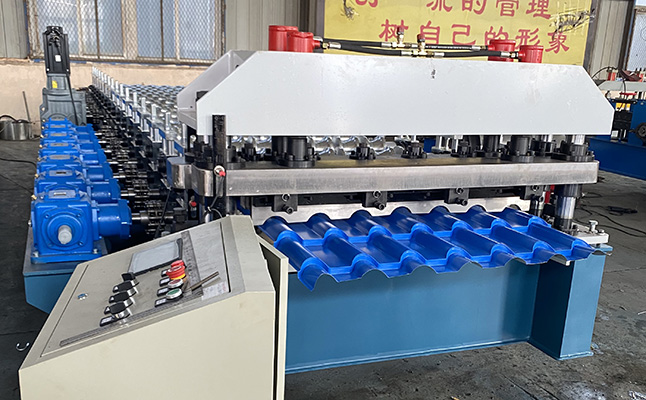

There are many parameters to be set for color steel equipment, which are set on the text screen. There are two types of parameter settings: equipment parameters and user parameters. Equipment parameters include: single pulse length, overshoot, profiling distance, profiling time, cutting knife time, etc. User parameters include: number of sheets, length, first section, last section, pitch, number of sections, etc.

The processing process of color steel tile equipment is as follows: the color steel plate enters the roller forming part, and after forming, it goes to the profiling part, and is pressed into a section-shaped plate shape with equal distances. The cutter is responsible for fixed length cutting. PLC electronic control introduction: The execution part includes the inverter drive motor, the hydraulic station motor, the two hydraulic solenoid valves for profiling, and the two hydraulic solenoid valves for cutting. The detection part includes: a pulse encoder for detecting the length of the color steel tile, an up and down stroke switch for profiling, an up and down stroke switch for cutting knife, an up and down operation button for profiling, an up and down stroke button for cutting knife, an emergency stop switch, a hydraulic start-stop switch, etc.

It can be roughly divided into three main parts:

Hydraulic part: The hydraulic system should pay attention to the cleanliness of the hydraulic oil to maintain the quality of the hydraulic oil. The hydraulic oil with good stability and high quality should be used. In addition to regular replacement, the working temperature should be properly controlled below 50C to avoid affecting the stability of the hydraulic action due to deterioration.

Mechanical part: The mechanical part should be regularly maintained and lubricated to reduce the friction coefficient and reduce wear. The nuts and locking screws on the head plate should be checked regularly to prevent the coring column from breaking due to uneven force. The mold thickness adjustment mechanism should regularly check whether the transmission shaft gear or chain is offset or loose. Whether the pressure plate screws on the gear are loose, whether the lubricating grease is sufficient, etc.

Electrical control part: Traditional injection molding machines use contact relays to switch various actions. They often fail due to loose contact screws and aging of contacts. Usually, they should be replaced with new ones after one million uses to ensure the stability of the electronic control. In particular, environmental factors such as dust adhesion and humid air will also affect the machine action. Modern injection molding machines use contactless integrated circuits, which greatly reduce the connection of wires, significantly reduce the adverse phenomena caused by wires, and improve stability.

Before use, check whether all connections, installed bolts and nuts are sufficient hydraulic oil in the hydraulic pump station, whether the electrical box circuit is connected to all parts of the machine. After the power starts to test run, first run the empty car carefully to observe whether there is vibration, noise, oil in the hydraulic pump, whether the moving parts are coordinated, and adjust the mold to the ceiling before the equipment is used. Normal, start operation.

During the operation of the tile press equipment, it is important to note that the equipment has a large power and automatic control, so pay attention during the operation.

Finally, it is also important to check the work of the color steel equipment, cut off the power supply, avoid short circuit caused by electronic components, such as electric machinery and electrical boxes, damage, cut off the power supply in thunderstorm weather, avoid damage caused by lightning water, etc.

How to use the tile press:

1. According to the moisture content of the yellow sand, adjust the amount of water added to each machine to make the mixture moist and suitable.

2. The mixing time for each time is not less than 120 seconds.

3. Make mixing records according to the mix ratio notice.

4. Before starting the color steel tile pressing machine, first check whether the equipment and electrical appliances are in good condition, and the power supply should be cut off when leaving get off work.

5. When the color tile machine is running, do not put a shovel or other objects into the mixer.

6. If the operator needs to enter the mixer for inspection, cut off the power supply and assign a special person to supervise.

7. The operator should pay attention to the operating environment. Such as the hopper, the position of the discharge port, etc.

8. Non-operating personnel are not allowed to operate casually.

Copyright © Cangzhou Guochen Cold Bending Machinery Equipment Co., Ltd. Rights Reserved Sitemap | Technical Support