Price:

Detailed Introduction

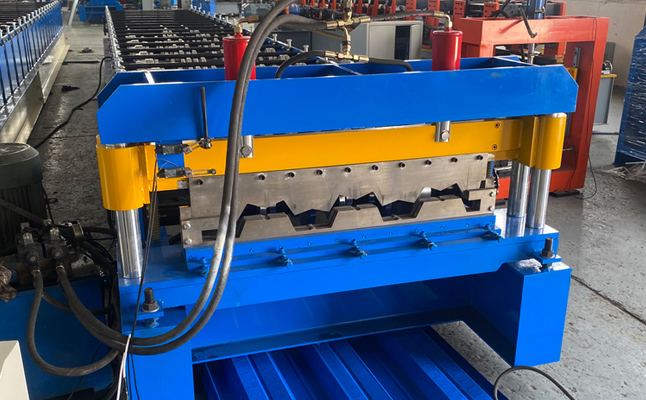

The products produced by floor decking equipment are characterized by light weight,high strength,heavy load-bearing capacity and good earthquake resistance.Floor decking equipment is widely used in the field of multi-story steel structure buildings.Floor decking equipment meets the requirements of rapid construction of the main steel structure,can provide a firm working platform in a short time,and can adopt multiple floors to lay corrugated steel plates and pour concrete slabs in layers.During the use stage,the floor decking is used as the tensile reinforcement of the concrete floor slab,which also improves the rigidity of the floor slab and saves the amount of steel bars and concrete.

Floor decking equipment products are widely used in power plants,power equipment companies,car showrooms,steel structure workshops,cement warehouses,steel structure offices,airport terminals,railway stations,stadiums,concert halls,theaters,large supermarkets,logistics centers,Olympic venues and stadiums and other steel structure buildings.

Manual placement and removal of blanks:Before using the equipment,check whether the connections are firm,whether the mounting bolts and nuts are tightened,and whether the left and right chassis should be filled with lubricating oil before the machine can be powered on for trial operation.First,run the machine empty and observe carefully whether there is vibration,noise,whether the oil window is oiled,and whether the movement of each component is coordinated.The mold can be installed after everything is normal.When installing the mold,the power must be cut off,and the motor belt or large gear is moved manually to make the workbench turn and the slide rise to the highest point.It is best to use an object to support between the workbench and the bottom of the slide to prevent the slide from falling naturally and causing accidents.

The mold used in this machine requires an upper mold and six lower molds of the same specifications and sizes.First install the upper mold and a lower mold.The lower mold is directly installed on the hexagonal rotary workbench,and the upper mold is installed on the bottom of the slide.Place a pad of appropriate thickness to ensure that the gap around the upper and lower molds is uniform after the upper and lower molds are closed,and the distance between the upper and lower molds is equal to the thickness of the required tile blank.Then take the upper mold as the standard,turn the workbench,install the remaining five sets of lower molds,and start the machine to press tiles only after all the upper and lower molds are installed.

Automatic unloading and blank taking work procedures:mold installation and host test run are the same as above,then start the air compressor,vacuum pump,extruder,tile cutter,unloading machine,tile press,host and tile support conveyor.When stopping,stop the extruder first,and then stop the rest of the equipment.

Main features of floor deck equipment

1.It can meet the requirements of rapid construction of the main steel structure,provide a firm working platform in a short time,and can use multiple floors to lay corrugated steel plates and pour concrete slabs in layers.

2.During the use stage,the floor deck is used as the tensile reinforcement of the concrete floor slab,which also improves the rigidity of the floor slab and saves the amount of steel bars and concrete.

3.The embossing on the surface of the corrugated plate creates a bonding force between the floor deck and the concrete,so that the two form a whole,and with stiffening ribs,the floor deck system has high strength bearing capacity.

4.Under cantilever conditions,the floor deck is only used as a template.The length of the cantilever can be determined according to the cross-sectional characteristics of the floor deck.In order to prevent the cantilever board from cracking,negative reinforcement should be provided at the support according to the design of the structural engineer.

The high configuration adopts control system technology,the parameter setting is simple and convenient,the degree of automation is high,the system has strong self-learning ability,the control components are all international brands,stable,high-precision automatic length measurement system,etc.The machine is installed on a good and stable foundation so that the machine will not vibrate during operation,thereby ensuring the accuracy and performance of the machine and extending its life.

Copyright © Cangzhou Guochen Cold Bending Machinery Equipment Co., Ltd. Rights Reserved Sitemap | Technical Support