TAG: Gypsum profile corner bead manufacturing machine Ceiling wall V-shaped corner beam plate rolling forming machine Metal iron rod gypsum board corner board forming machine

Price:

Detailed Introduction

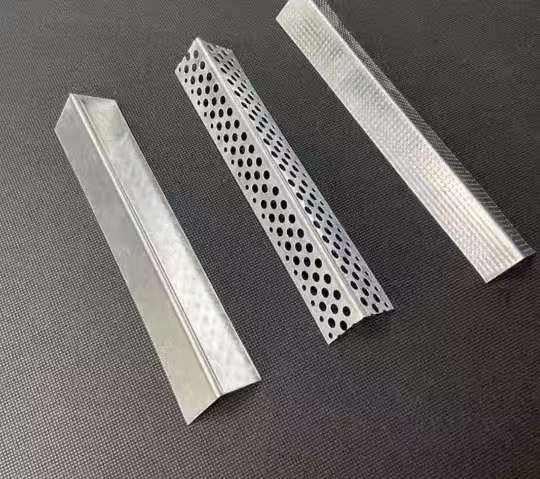

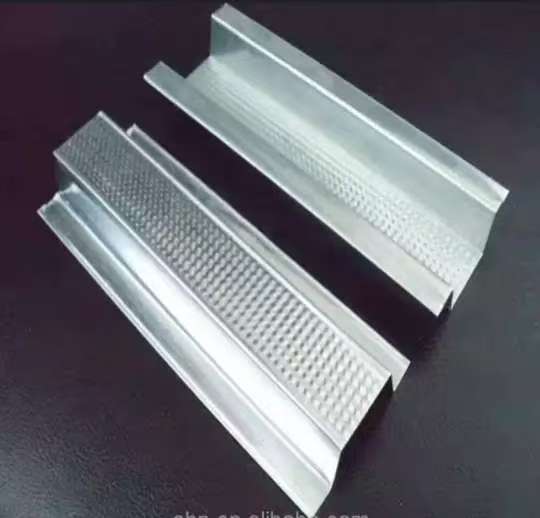

Here are some common gypsum profile corner bead manufacturing machines and related information:

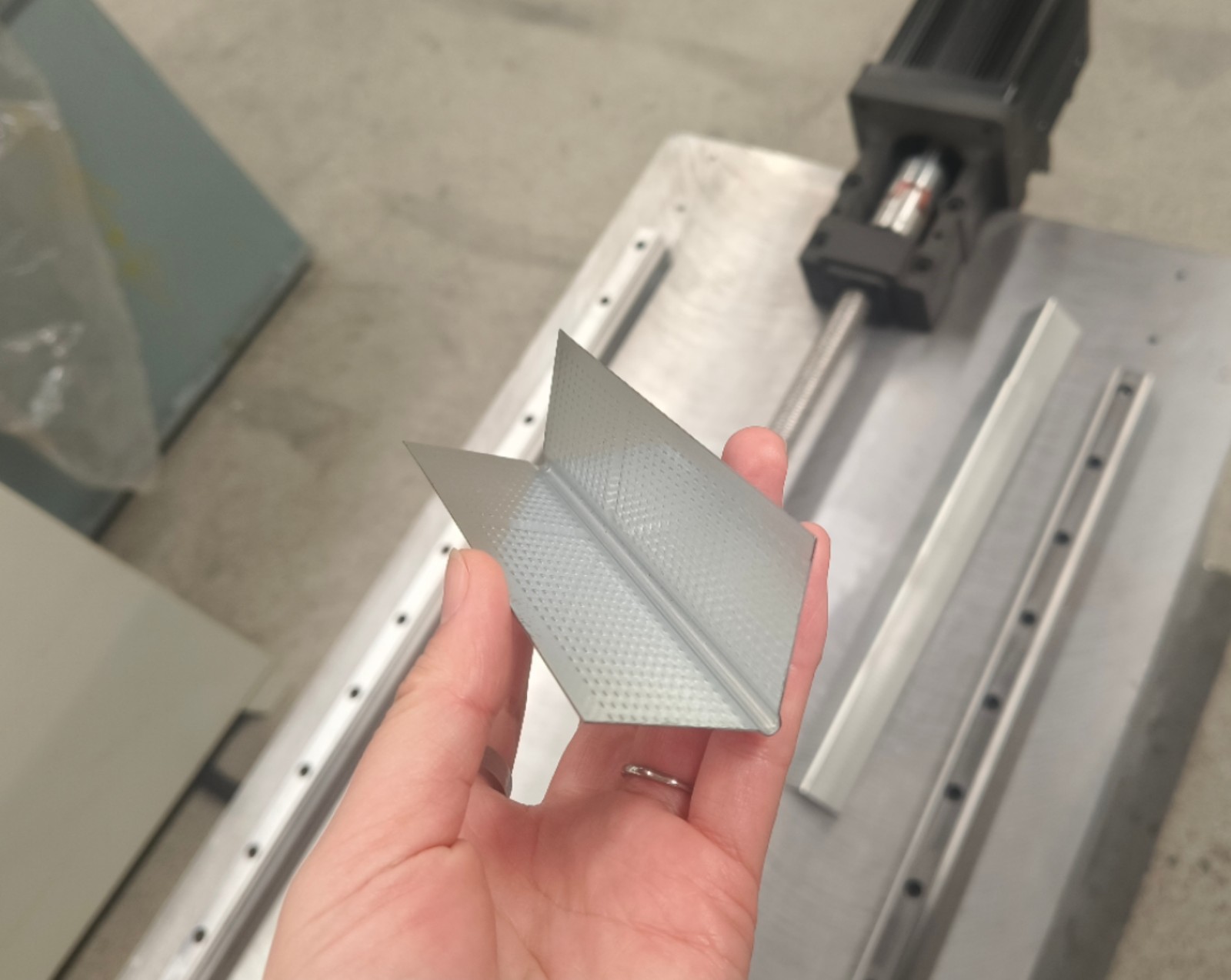

Gypsum corner bead forming machine

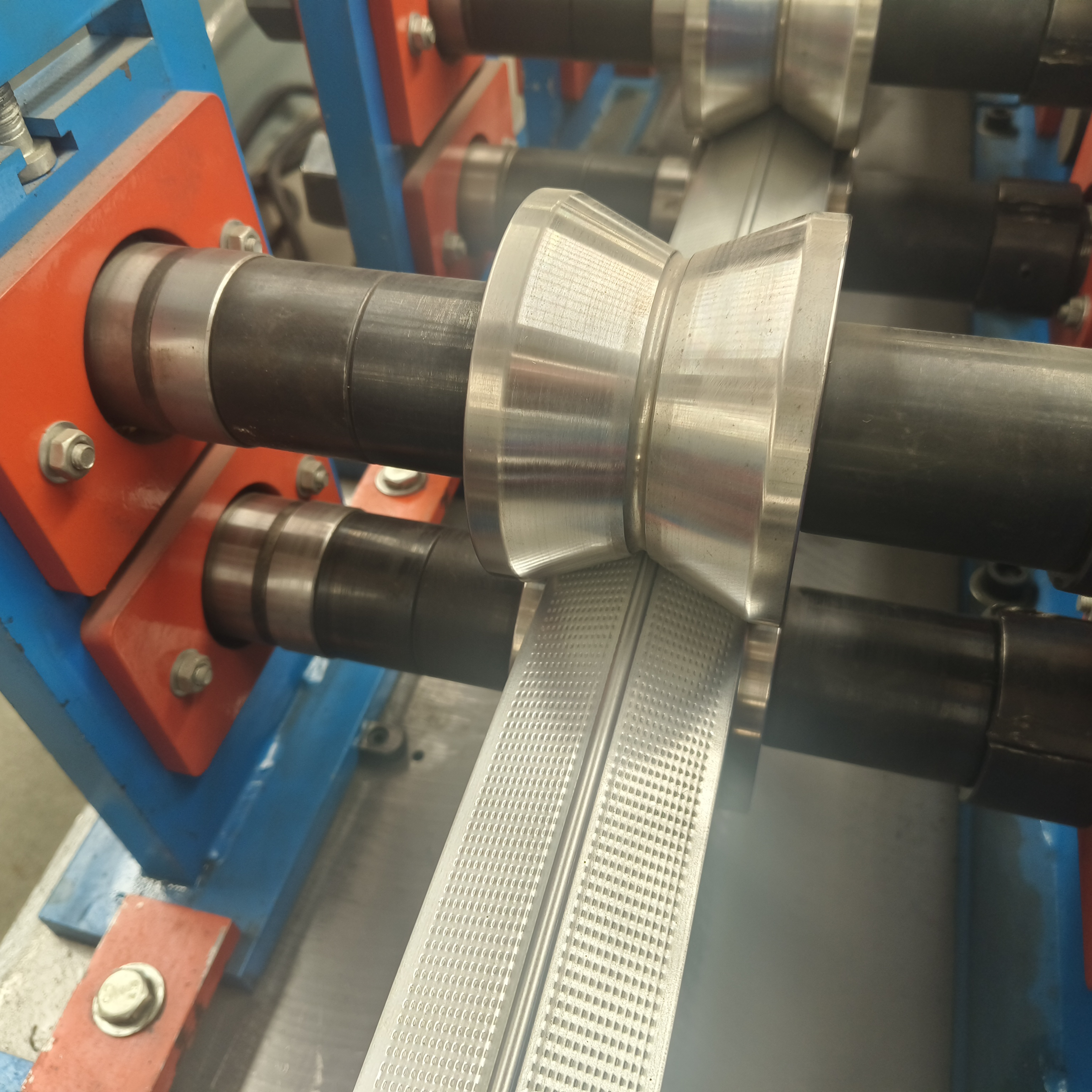

-Working principle: Usually, the mixed gypsum slurry is injected into a specific bead mold, and through the extrusion and molding of the mold, the gypsum slurry solidifies into the shape of beads inside the mold.

-Structural composition: generally includes a slurry conveying system, used to transport gypsum slurry to the mold; Mold system, which determines the shape and size of corner beads, usually consists of multiple components and can achieve the action of opening and closing the mold; The power system provides power for the operation of the machine, such as motors, hydraulic devices, etc.

Gypsum bead drying equipment

-Working principle: By using hot air circulation or other drying methods, the moisture in the formed corner beads is removed to achieve the specified dryness, thereby improving the strength and stability of the corner beads.

-Structural composition: Common types include hot air drying ovens, which are equipped with heating elements and circulating fans inside to ensure even flow of hot air inside the oven; There are also those that use tunnel type drying furnaces, where the corner beads slowly move through the tunnel through a conveyor belt and pass through different temperature zones to achieve drying.

Gypsum corner bead processing auxiliary equipment

-Mixing equipment: used to thoroughly mix gypsum powder with water and other additives to produce gypsum slurry with good fluidity and plasticity. It is generally composed of a mixing drum, mixing blades, and a driving motor.

-Cutting equipment: If the corner beads need to be resized or cut to a specific length after forming, cutting equipment such as small electric saws or laser cutting machines will be used. The cost of electric saw cutting is relatively low, but the accuracy is relatively low; Laser cutting machines have high cutting accuracy, but their equipment and operating costs are relatively high.

The gypsum profile corner bead manufacturing machines produced by different manufacturers may have differences in specific structure and performance. When selecting, it is necessary to consider factors such as production scale, product quality requirements, and budget comprehensively.

Copyright © Cangzhou Guochen Cold Bending Machinery Equipment Co., Ltd. Rights Reserved Sitemap | Technical Support