Price:

Detailed Introduction

The precision and efficiency revolution of rolling shutter door forming machine

In the grand map of modern industrial production, as an indispensable protective and functional facility for various buildings, the core of its production and manufacturing - the rolling shutter door forming machine, is reshaping the development pattern of the industry with unparalleled precision and efficiency. This precision equipment is like an tireless master craftsman, carving cold metal sheets into sturdy, durable, beautiful, and practical rolling shutter doors. Each process embodies the ultimate pursuit of industrial manufacturing.

1、 Precision first: Crafted with millimeter level craftsmanship

The precision of the rolling shutter door forming machine is unparalleled, as it can accurately process metal sheets to the millimeter level or even finer. During the molding process, the bending curvature of the board, punching position, and dimensional tolerances of each component are strictly controlled within a very small range. This high precision means that every component of the rolling shutter door can perfectly fit together. The assembled rolling shutter door not only has a smooth and seamless appearance, but also runs smoothly and steadily during use, greatly reducing the noise and fault risks caused by mismatched components.

With high-precision molds as the core, the rolling shutter door forming machine is equipped with advanced CNC systems and precision transmission devices. The CNC system is like the brain of a device, accurately issuing every command to control the motion trajectory and pressure of the mold; The transmission device is like a strong muscle, stably and accurately transmitting power to the mold, ensuring that the mold can still maintain extremely high positioning accuracy during high-speed operation. Even for complex irregular roller shutter door designs, the molding machine can strictly follow the preset program and complete the processing without any deviation, truly achieving the perfect transformation from design drawings to physical products, meeting the market's diverse and personalized needs for roller shutter doors.

2、 Efficiency Pioneer: High Speed Running Production Engine

In addition to stunning precision, the efficiency of the rolling shutter door forming machine is also remarkable. In modern production workshops, molding machines operate at high speeds and become powerful engines that drive production efficiency. The traditional production method of rolling shutter doors is cumbersome, with a large proportion of manual operations, long production cycles, and low efficiency. Nowadays, molding machines have achieved automation and continuous production, greatly reducing production time.

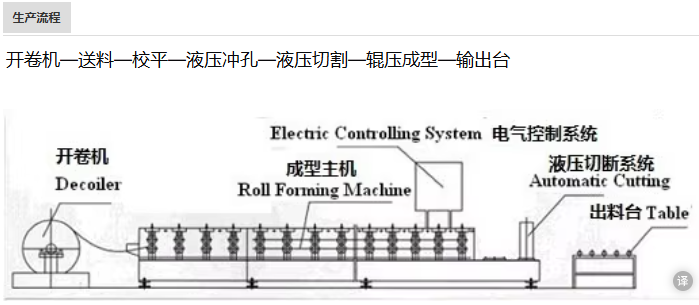

The molding machine adopts advanced automated feeding, stamping, forming, and cutting processes, with each link closely connected and completed in one go. After being fed into the forming machine, the sheet metal is quickly and orderly shaped by an invisible hand, completing a magnificent transformation from raw materials to finished rolling shutter doors in a short period of time. It can produce rolling shutter doors several meters or even longer per minute, which is several times or even tens of times more efficient than traditional production methods. This not only enables enterprises to quickly respond to market orders and meet the growing market demand, but also effectively reduces production costs, improves the economic efficiency and market competitiveness of enterprises.

3、 The perfect integration of precision and efficiency: a booster for industry transformation

The high precision and high efficiency of the rolling shutter door forming machine do not exist in isolation, but promote and complement each other, jointly driving the transformation and development of the rolling shutter door industry. High precision ensures the quality and performance of the product, enabling the roll to

Copyright © Cangzhou Guochen Cold Bending Machinery Equipment Co., Ltd. Rights Reserved Sitemap | Technical Support