Price:

Detailed Introduction

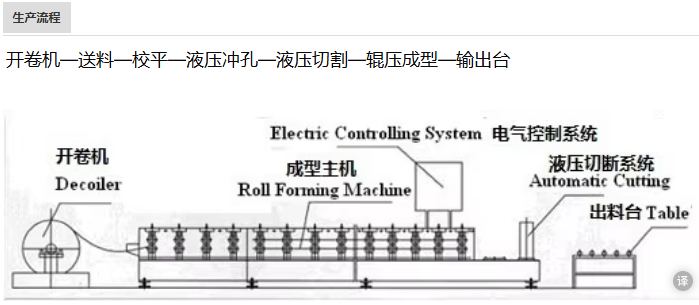

Multi purpose door frame lace forming machine is a professional mechanical equipment used for processing door frames and door frame lace. The following introduces its working principle, structural composition, performance characteristics, and application fields:

Working principle

By driving with a motor and using methods such as rolling and stamping, metal sheets are cold-formed to gradually process flat metal materials into door frames and lace profiles with specific shapes and sizes.

Structural composition

-Material discharge device: including flat material discharge rack and roll material discharge rack, used to place metal sheets to be processed.

-Guided feeding device: guides the sheet metal accurately into the forming machine, ensuring smooth and accurate feeding.

-Forming host: the core component that continuously rolls the sheet metal through multiple sets of rollers, and can replace different rollers to produce profiles with different cross-sections.

-Straightening mechanism: Straighten the formed profiles to ensure their straightness and flatness.

-Hydraulic cutting device: automatically cuts the profile to a fixed length according to the set length, with a smooth cut.

-Control system: Mechanical control system or PLC control system can be used to achieve automatic control of equipment.

Performance characteristics

-Multi purpose: By replacing components such as rollers, it can produce a variety of door frames and lace profiles of different specifications and shapes, suitable for various door industries such as anti-theft doors and fireproof doors.

-High precision molding: capable of accurately controlling the size and shape of profiles, ensuring the accuracy and consistency of door frames, and improving product quality.

-Easy to operate: The operation of the equipment is relatively simple, and workers can master it proficiently after certain training, reducing the requirement for the technical level of operators.

-High production efficiency: With a high degree of automation and fast work line speed, it is possible to complete the production of a large amount of door frame lace in a short period of time.

-Good stability: The equipment structure design is reasonable, the quality of each component is reliable, and it can maintain good performance during long-term operation, reducing failures and downtime.

application area

It is mainly used in the production enterprises of various types of doors such as anti-theft doors, fireproof doors, steel doors, aluminum alloy doors, etc. It is used to produce door frames and lace decorative profiles on door frames. It can also be used in some metal product processing enterprises to produce metal profiles with special shapes and requirements.

Copyright © Cangzhou Guochen Cold Bending Machinery Equipment Co., Ltd. Rights Reserved Sitemap | Technical Support