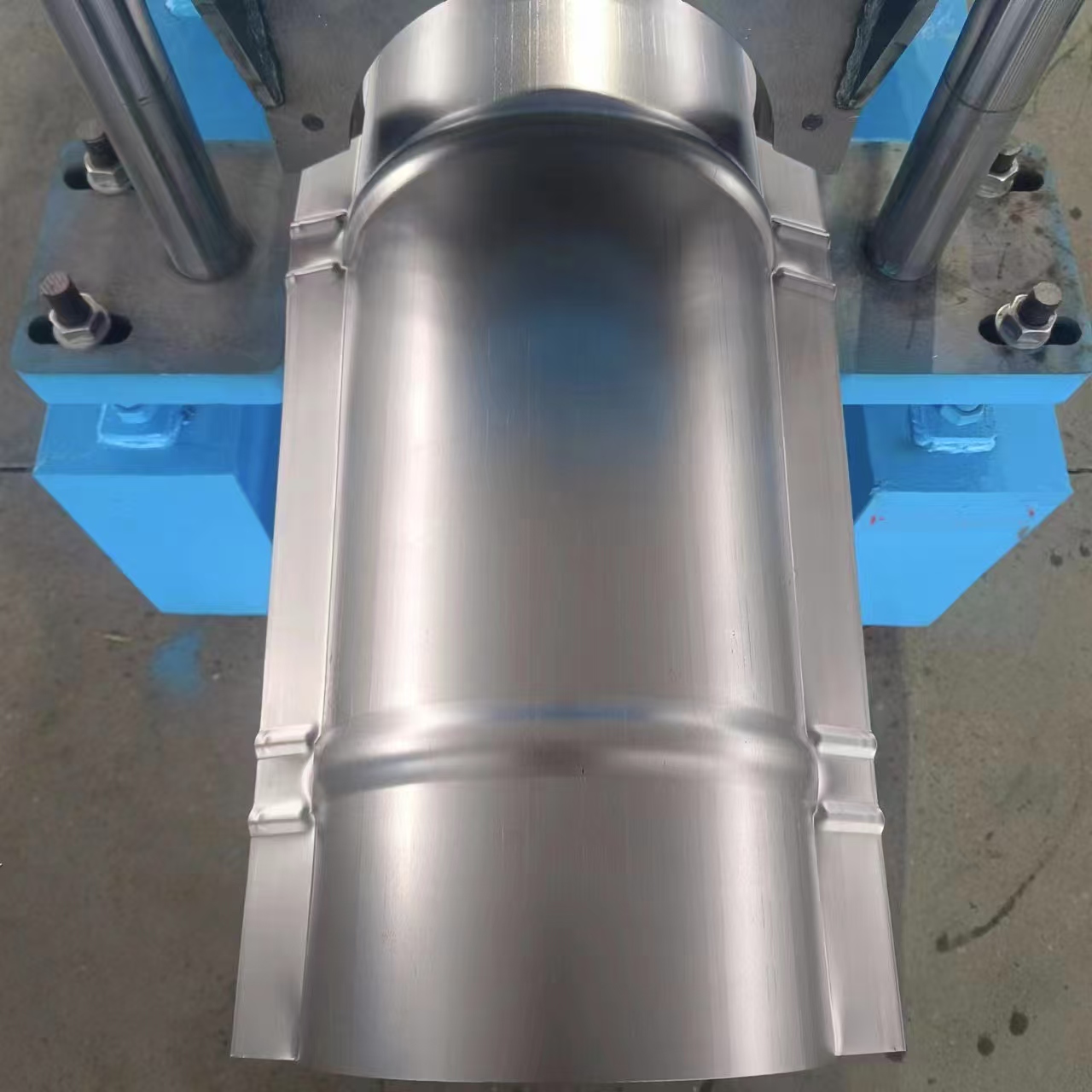

TAG: Roof ridge cover rolling forming machine 312 ridge cover cold rolling mill forming machine Roof tile manufacturing machinery

Price:

Detailed Introduction

The following is an introduction to the usage and application of the 312 ridge cover rolling forming machine:

Usage

Preparation work: Check whether all components of the equipment are normal, whether the lubrication parts are lacking oil, whether the circuit system is connected correctly and without leakage, and other issues. Select and install suitable molds according to the specifications of the required ridge cover, and adjust the gaps and positions of the molds. Place the coil raw materials on the feeding rack, ensuring that the coil is placed smoothly and the center of the coil is aligned with the center of the equipment feeding port.

Equipment debugging: Connect the power supply, start the equipment, perform idle debugging, observe whether the equipment runs smoothly, and whether there are any abnormal noises in the transmission components. According to the size requirements of the ridge cover, set the rolling speed, feed length, cutting length and other parameters through the controller.

Feed rolling: Introduce one end of the coil into the feeding port of the equipment, start the feeding device, and slowly feed the coil into the rolling forming machine. The rolling wheel of the equipment will gradually roll the roll material, forming it into the shape of a ridge cover according to the shape of the mold. During the rolling process, attention should be paid to observing the feeding situation and forming effect of the coil. If there are problems such as deviation or non-standard forming, stop the machine in time for adjustment.

Cut off discharge: When the ridge cover is rolled to the set length, the cutting device will automatically cut it off. The finished ridge cover after cutting will be transported to the designated location through the discharge device, completing one production cycle.

Equipment cleaning and maintenance: After production is completed, turn off the power, clean up debris and waste on the equipment, and perform necessary maintenance on the equipment, such as adding lubricating oil, cleaning molds, etc., to extend the service life of the equipment.

application

-In the field of architecture, it is used to manufacture ridge covers in various industrial and civil buildings, and to carry out waterproof, windproof, and decorative treatments on the roof ridge to enhance the overall performance and aesthetics of the roof. For example, roof construction of steel structure factories, residential buildings, commercial buildings, etc.

-Agricultural facilities: The roof ridge of agricultural greenhouses and other facilities is often covered with ridge caps produced by the 312 ridge cap rolling forming machine, which plays a sealing and protective role and creates a good environment for crop growth.

-Temporary buildings: In some temporary constructions such as activity board houses, disaster relief tents, etc., the products produced by the ridge cover rolling forming machine can be quickly assembled, providing people with temporary living and use space.

Copyright © Cangzhou Guochen Cold Bending Machinery Equipment Co., Ltd. Rights Reserved Sitemap | Technical Support