Price:

Detailed Introduction

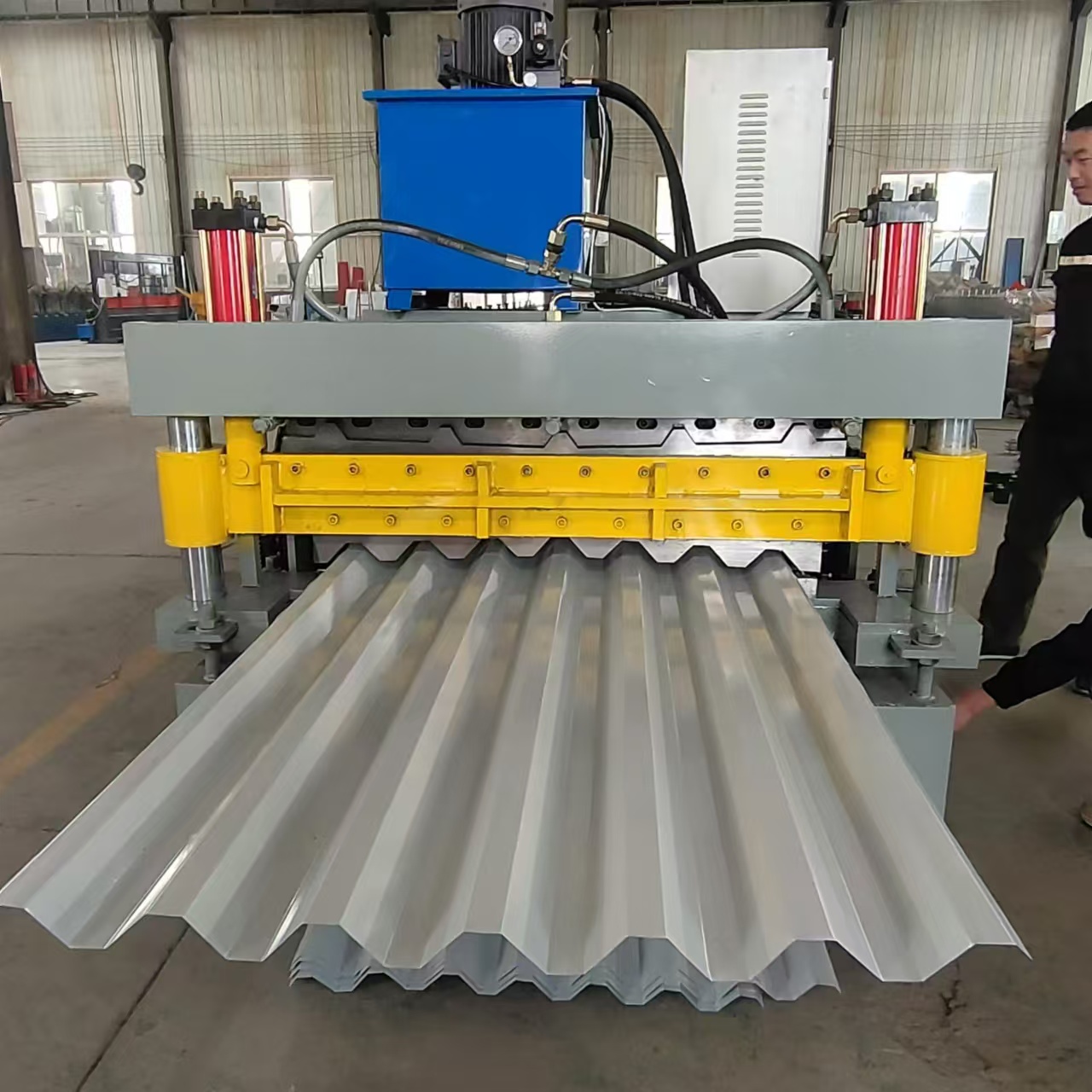

Metal roof deck floor machine usually refers to the molding mechanical equipment used for producing metal roof panels, decks, and floors. The following is a related introduction:

Working principle

Usually, the principle of cold bending or rolling forming is used. The metal coil or sheet is placed on the feeding rack, and the material is transported to the guiding feeding device through the feeding device to accurately enter the forming host. In the forming host, multiple sets of rollers are designed according to specific shapes and sizes to continuously roll metal materials, gradually bending and pressing them into the desired shape of roof panels, decks, or floors. Some equipment may also be equipped with heating devices to moderately heat metal materials to improve their formability.

Structural composition

-Material feeding device: a feeding rack used to place metal coils or sheets, some of which are also equipped with automatic feeding and unwinding functions.

-Guided feeding device: guides metal materials accurately and smoothly into the forming machine, ensuring the accuracy and stability of feeding.

-Forming host: The core component consists of multiple sets of rollers, and the shape and size of the rollers are designed according to the cross-sectional shape and specifications of the product.

-Cutting device: It uses hydraulic or mechanical cutting methods to cut the formed metal sheet to a fixed length according to the set length.

-Control system: composed of PLC, frequency converter, operation interface, etc., to achieve automatic control of equipment.

Performance characteristics

-High precision molding: It can accurately control the size and shape of the product, ensuring the accuracy and consistency of metal roof panels, decks, and floors.

-High production efficiency: With a high degree of automation and fast work line speed, it can produce a large number of products in a short period of time.

-Easy to operate: Equipped with a user-friendly interface, workers can proficiently operate after simple training.

-Multifunctionality: By replacing rolling mill molds and other components, a variety of metal roof panels, decks, and floors with different specifications, shapes, and uses can be produced.

-Good stability: The structural design is reasonable, the quality of each component is reliable, and it runs stably for a long time.

application area

Widely used in the construction industry for the production of metal roof panels for various industrial plants, sports venues, exhibition halls, etc; It can also be used in the field of shipbuilding to produce ship decks; Used for producing metal flooring in some special buildings or places with special requirements for the ground.

Copyright © Cangzhou Guochen Cold Bending Machinery Equipment Co., Ltd. Rights Reserved Sitemap | Technical Support