Price:

Detailed Introduction

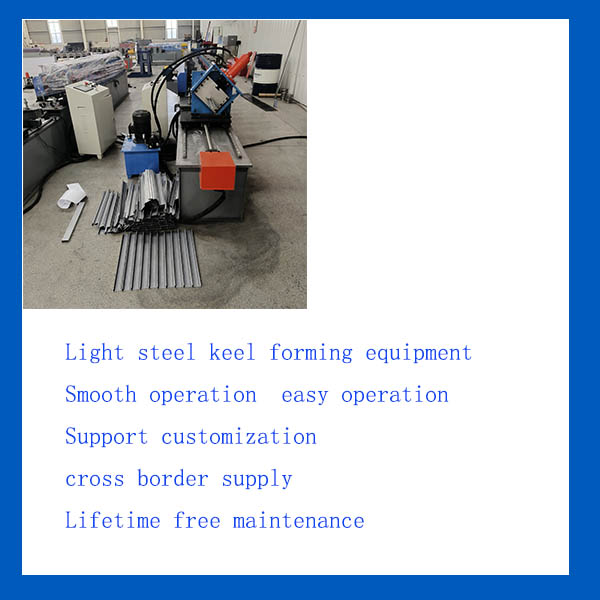

The forming process of the light steel keel machine includes the following specific steps:

Loading: Fix the light steel material on the automatic feeding rack and prepare for the forming process.

Flatness: By using a straightening system, the material is flattened to ensure its flatness.

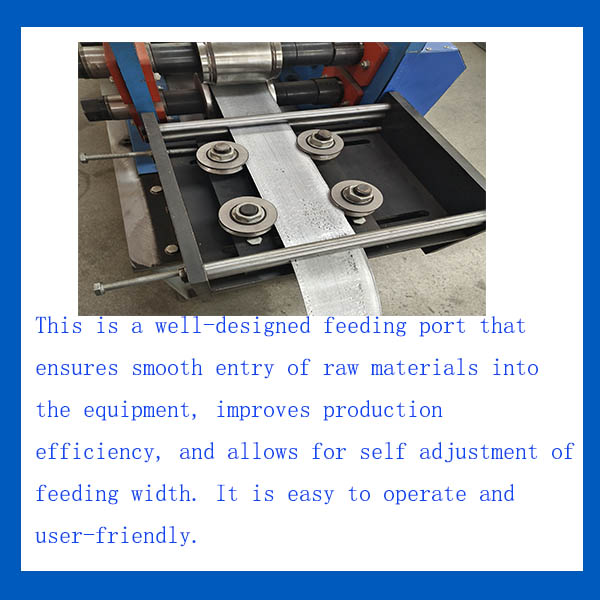

Material guide: Import materials from the feeding rack into the equipment, preparing for the next step of stamping and forming.

Stamping: Using molds to stamp materials into the desired shape of light steel keel.

Rolling: The material undergoes a rolling forming system and multiple forming groups to ensure stability and flatness during movement, making the formed keel material more aesthetically pleasing.

Lock buckle: Lock the formed light steel keel to ensure a secure connection and improve construction stability.

Spray code: Spray code and number the formed light steel keel to facilitate quick identification of connected components during subsequent assembly and improve construction efficiency.

Cutting: Cut the formed light steel keel to the required length to meet the actual construction requirements.

Copyright © Cangzhou Guochen Cold Bending Machinery Equipment Co., Ltd. Rights Reserved Sitemap | Technical Support