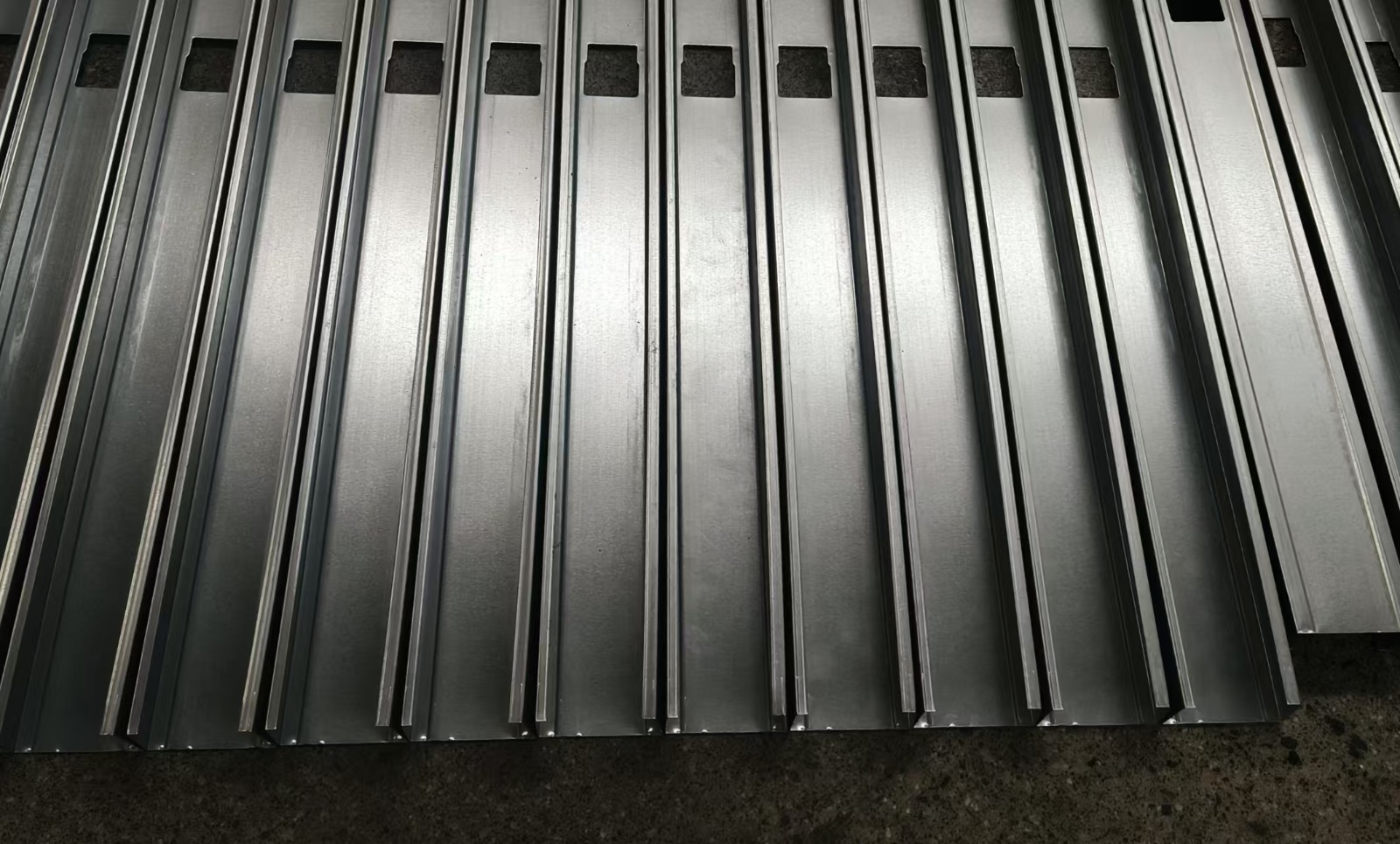

TAG: Dry wall profile machine C U galvanized sheet light steel keel profile machine Rail Roll Forming Machine

Price:

Detailed Introduction

The CU galvanized sheet light steel keel profile machine for drywall channels is a professional equipment used for producing CU type galvanized sheet light steel keels for drywall channels. The following is a related introduction:

Structural composition

-Material feeding device: usually composed of an uncoiler and other components, used to place and feed galvanized sheets into rolls, which can maintain the stability of the sheet during the feeding process and ensure the accuracy of subsequent processing.

-Guidance and leveling device: It guides and levels the incoming galvanized sheet by applying pressure to the sheet through multiple sets of rollers, eliminating deformation such as bending and twisting during transportation or storage, and allowing the sheet to enter the forming process in a flat state.

-Molding host: The core component consists of multiple sets of roller molds with different shapes. The roller molds are arranged in a specific order. As the galvanized sheet passes through, the rollers gradually roll the sheet, bending it into the shape of a CU type light steel keel.

-Cutting device: When the light steel keel profile reaches the set length, the cutting device will cut it. Common cutting methods include sawing, shearing, etc., which can ensure a smooth cutting surface and high dimensional accuracy.

-Control system: Generally, PLC control system is used to achieve automatic control of equipment. Operators can set production parameters such as profile length and production speed on the control interface, and the system will accurately control the operation of each component.

Working principle

The CU galvanized sheet light steel keel profile machine for drywall channels uses galvanized sheet as raw material and uses a motor to drive the rollers to rotate, driving the galvanized sheet to move between various roller molds. During the movement, the roller mold applies pressure in different directions and sizes to the galvanized sheet, causing plastic deformation of the sheet and gradually forming it into a CU type light steel keel according to the shape of the roller mold. The control system precisely coordinates the operation of each component to ensure the stability of the production process and the consistency of product quality.

Performance characteristics

-High production efficiency: With a high degree of automation, continuous production can be achieved, and several meters of light steel keel profiles can be produced per minute, which can meet the needs of large-scale drywall construction projects.

-Good product quality: The CU type light steel keel produced has high dimensional accuracy, with errors controllable within a small range, smooth surface, no obvious scratches, burrs or other defects, uniform galvanized layer, and strong corrosion resistance.

-Strong material adaptability: It can adapt to galvanized sheets of different thicknesses and widths. By adjusting equipment parameters, it can produce various specifications of CU type light steel keel to meet different requirements for drywall design and construction.

-High stability and reliability: The equipment is made of high-quality steel and components, with a sturdy structure and key components that have been specially treated to maintain stable performance under long-term high load operation, reducing the frequency of failures.

Copyright © Cangzhou Guochen Cold Bending Machinery Equipment Co., Ltd. Rights Reserved Sitemap | Technical Support