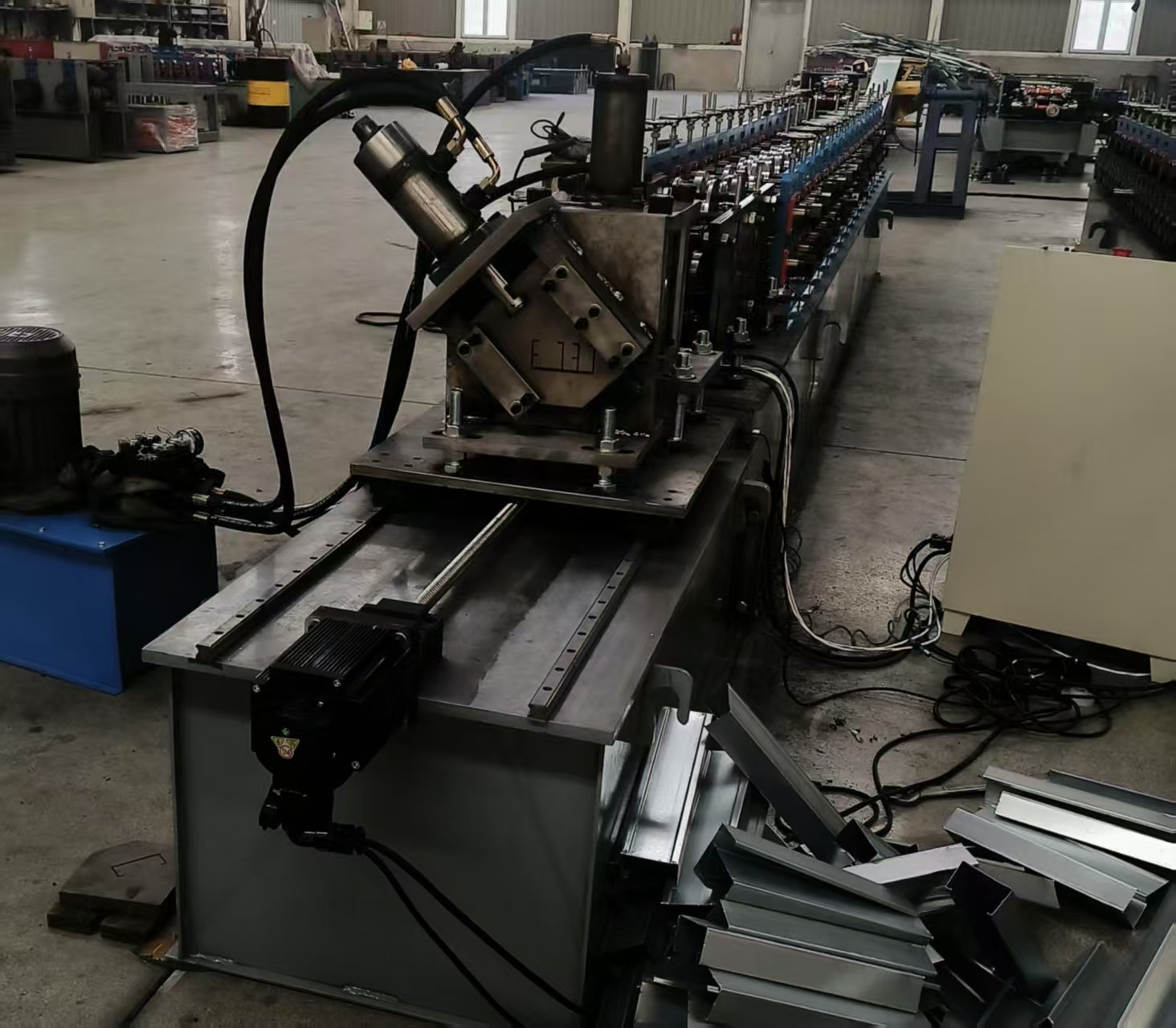

TAG: 50 75 100 drywall metal profile machine Dry wall steel frame construction machinery CD UD CW UW Roll Forming Machine

Price:

Detailed Introduction

The introduction of mechanical equipment for drywall frame construction can be elaborated from several dimensions, including common types, working principles, advantages, and application scenarios:

Common types

-Light steel keel machine: specifically used for producing light steel keels, including different shapes such as C-shaped, U-shaped, T-shaped keels, etc., providing the main support structure for drywall frames.

-Gypsum board cutting equipment: used to cut gypsum board into suitable sizes and shapes for installation on light steel keel frames. Common types include manual cutting knives, electric cutting saws, etc.

-Nail gun: By firing nails, light steel keel can be fixed to the building structure, or gypsum board can be fixed to the keel, which is easy to operate and can improve construction efficiency.

-Self tapping screw gun: used to connect and fix gypsum board and light steel keel with self tapping screws, ensuring a firm connection and adjusting the tightening force of the screws as needed.

Working principle

-Light steel keel machine: Using the principle of rolling forming, metal sheets are gradually deformed through a set of roller molds under the pressure of rollers, producing light steel keels of specific shapes and sizes.

-Gypsum board cutting equipment: a manual cutting knife cuts open the paper layer on the surface of the gypsum board with a sharp blade, and then breaks the gypsum board; Electric cutting saws use high-speed rotating saw blades to cut gypsum boards.

-Nail gun: Using compressed air, gunpowder gas, or electromagnetic force as power, it quickly shoots nails and injects them into building structures or materials.

-Self tapping screwdriver: The screwdriver head is driven by a motor to rotate, and the self tapping screw is screwed into the gypsum board and light steel keel to achieve the connection between the two.

advantage

-Fast construction speed: Mechanized operation greatly improves the installation speed of drywall frames and shortens the overall construction period.

-Stable quality: It can ensure the dimensional accuracy of light steel keel and the installation flatness of gypsum board, making the quality of drywall frame more stable and reliable.

-Low labor intensity: reduces the workload of manual operations and lowers the labor intensity of workers.

-Strong operability: The equipment operation is relatively simple, and workers who have received simple training can proficiently operate it.

Application scenarios

-Residential buildings: widely used in the construction of drywall frames such as partition walls and ceilings in home decoration.

-Commercial buildings: drywall projects such as indoor partitions, ceilings, and suspended ceilings in places such as office buildings, shopping malls, and hotels.

-Public buildings such as schools, hospitals, and libraries often use drywall frame construction machinery and equipment for internal space separation and decoration.

Copyright © Cangzhou Guochen Cold Bending Machinery Equipment Co., Ltd. Rights Reserved Sitemap | Technical Support